REPAIR – OVERHAUL – MAINTENANCE OF COAL MILL/BALL MILL (PART 3 – SCREW CONVEYOR)

II. SCREW CONVEYOR

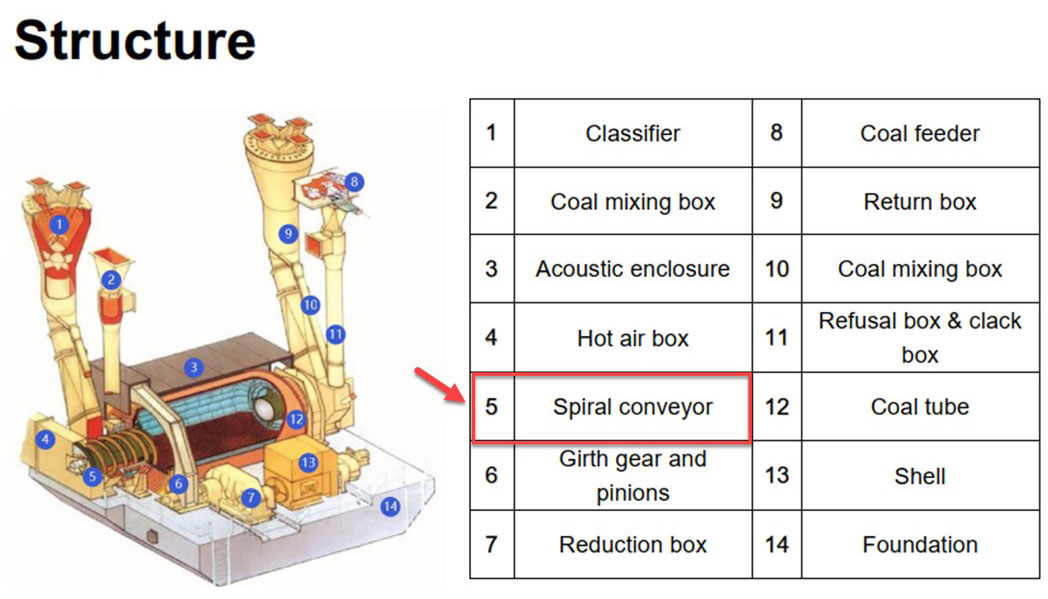

1. Position

- The position of the screw

2. Common problems

- Bolts, screws wear out and loosened

- Deformed, rusted

3. The process of overhauling - repair - maintenance of screw conveyor

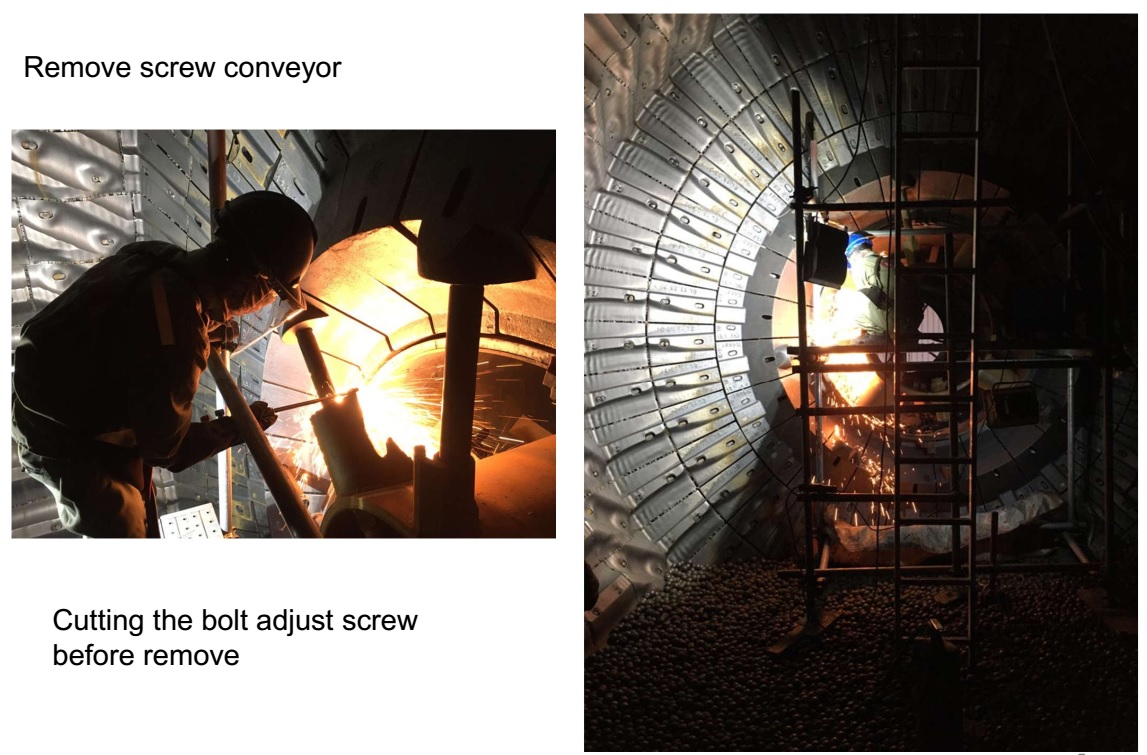

- Step 1: Remove the cover, remove the screw bearing from the ball mill.

- Step 2: Take the cover out of the ball mill

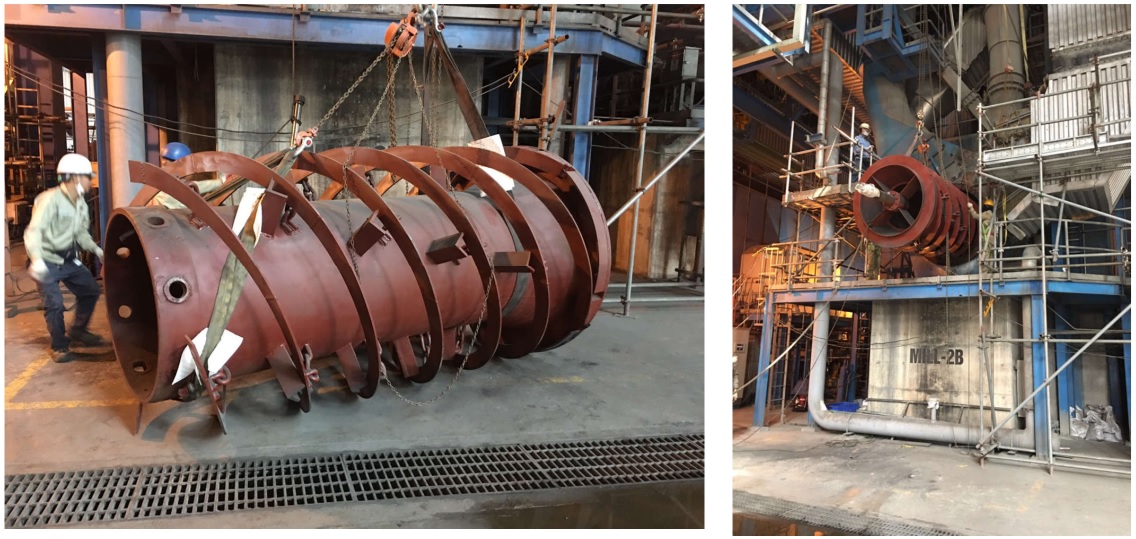

- Step 3: Disassemble the screw, cut the adjusting bolt before removing. Take the screw out of the mill to the repair area

- Step 4: Clean all cover surfaces. Prepare new screws, clean, grind and remove damaged bolts.

- Step 5: Assembly screw conveyor to ball mill

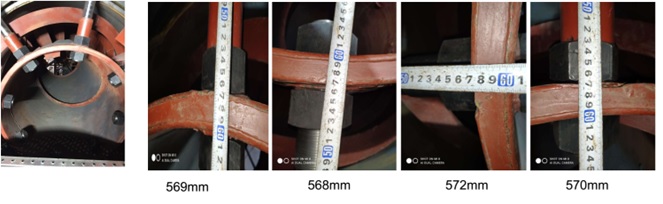

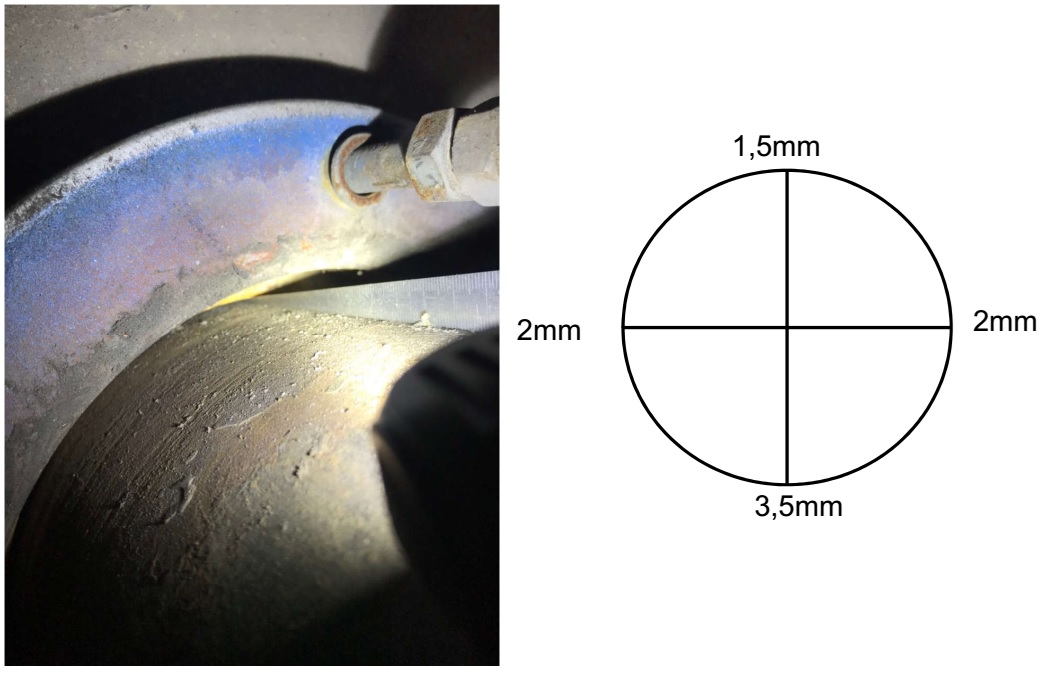

- Step 6: Fitting bolt and nut for adjusting the screw conveyor. Align screw inside ball mill.

- Step 7: Welding adjust the nut to screw

- Step 8: Fitting cover to ball mill

- Step 9: Fitting cover to ball mill. Adjust cover of bearing to center.

Contact us via hotline +84962879247 for detailed consultation